Between 1996 and 1999, I spent many hours inside the Pittsburgh Wool plant taking photos and talking with the company’s owners, Jeff Kumer and his father, Roy (1908-2004). I pored over the company’s voluminous business records, looked at photographs, and recorded several hours of audio interviews with the Kumers and several of their workers.

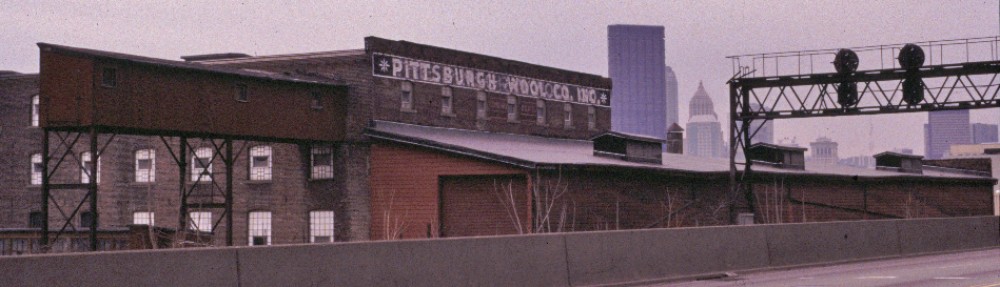

Pittsburgh Wool Company as seen from Pennsylvania Route 28, 1997.

The company occupied a four-story former tannery building. The interior had been divided into specialized spaces related to the work done there. For example, the second floor dedicated to wool pulling, drying, and baling. The upper floors were used to store pelts (in later years).

Pittsburgh Wool Company, HAER No. PA-572, Sheet 5.

In the company’s later years, all of the raw materials entered and left the plant via the first floor. Lamb pelts entered and pickled lamb skins and baled wool left. The first floor included washing vats for the pelts and metal tables where depilatory was painted on the skins to loosen the wool for pulling.

Jeff Kumer (left) and Keith White (right) painting and folding pelts, February 2000.

Once the wool was removed on the second floor, the skins were dropped through holes in the floor into large rotating drums on the first floor where they were pickled before being sent to tanneries.

Lamb skins after pulling being dropped into a hatch in the second floor above a rotating pickling drum on the first floor. The people observing include a documentary film crew and Heinz History Center staff. February 2000.

Pickle drum, first floor, Pittsburgh Wool Company.

Most of these spaces were documented in detail in 2000 for the Historic American Engineering Record (HAER). The measured drawings and my narrative report are archived at the Library of Congress. If you want to learn about the technology and material culture of wool pulling, those are the places to get your fix.

Pittsburgh Wool Company, HAER No. PA-572, cover sheet.

But if you want to learn about the people who kept the company going for more than half a century after the Kumer family bought it, you’ll be left feeling unfulfilled by the HAER documentation. I had always intended to write something more detailed about the business and its people but real life kept getting in the way.

Pittsburgh Wool Company office (highlighted), Pittsburgh Wool Company, HAER No. PA-572.

The office was one of the undocumented spaces inside the Pittsburgh Wool Company building. In the HAER drawings it’s simply represented as a box along the River Avenue facade. Yet, inside that box there were two offices: an outer office that served as a reception area and an inner office where the Kumers had their desks. They both worked in view of a portrait of the company’s founder, W.P. Lange.

Roy (seated) and Jeff Kumer inside the Pittsburgh Wool Company office, 1997.

Off to the side was another room that the Kumers used as a kitchen. The HAER architects didn’t draw plans for these spaces and I never took any pictures of them. Now, more than 20 years later, it’s one of the fieldwork mistakes that I will always regret.

Pittsburgh Wool Company, HAER No. PA-572, Sheet 5. The office is in the lower right.

Inside those spaces Roy Kumer worked his magical calculations to determine precisely how many pelts the company needed to buy from particular meatpackers around the nation. “I give credit to my dad for this,” Jeff Kumer told me in 1997. “He worked out his own book keeping process that he would be able to predict from year to year, when that month’s production came along from that particular plant.”

The telephones inside the offices connected the Kumers to a global network of meatpackers, textile mills, and leather tanners. Their files documented more than a century of institutional knowledge.

The business spaces seem like the most obvious to have mapped and more fully documented and they should have been. But so too was the kitchen. That’s where each day Jeff and Roy would adjourn mid-day to eat lunch together. I fondly recall the days when I was doing research in the plant when Jeff would invite me into the kitchen for some soup and a sandwich.

On August 5, 1999 I did my fourth interview with the Kumers inside the building. By that time a deal had been hammered out for the neighboring Heinz Company to acquire the Pittsburgh Wool Company property after a contentious battle that included a threat by the City of Pittsburgh to use eminent domain to seize the property. Sometime in the next year, the old tannery building was to be demolished to be replaced by a new Heinz warehouse.

Jeff Kumer and I sat in the kitchen where I asked my questions with a tape recorder sitting on the table between us. I returned to the plant two other times. The first was in February 2000 to witness a final run of pelts through the plant for a documentary produced by the Heinz History Center as part of the mitigation package agreed upon the year before. The second time was in the summer of 2000 when I drove from Charleston, West Virginia, to Pittsburgh to collect a few artifacts that Kumer wanted to give me before they were to vacate it prior to its demolition.

Pittsburgh Wool Company demolition.

One of the artifacts Kumer gave me was completely unrelated to the pulling of wool or processing of skins. It was a cream-colored ceramic soup bowl from the company’s kitchen. It’s an ordinary earthenware bowl with no maker’s marks or other markings. I have kept it on a shelf in all of the home offices I have had since then.

Soup bowl, Pittsburgh Wool Company.

I wish that I had asked questions about the kitchen and the Kumers’ attachment to it. I also wish that I had done a more complete job documenting the non-industrial spaces inside the plant. Over the years since I first set foot inside the Pittsburgh Wool Company building in 1996, I have learned a lot about space and its many uses. Those spaces were integral to the company’s history and they represented a critical social part of the Pittsburgh Wool Company’s story that isn’t preserved in documents, photographs, or the interviews with the people who worked there.

© 2020 D.S. Rotenstein